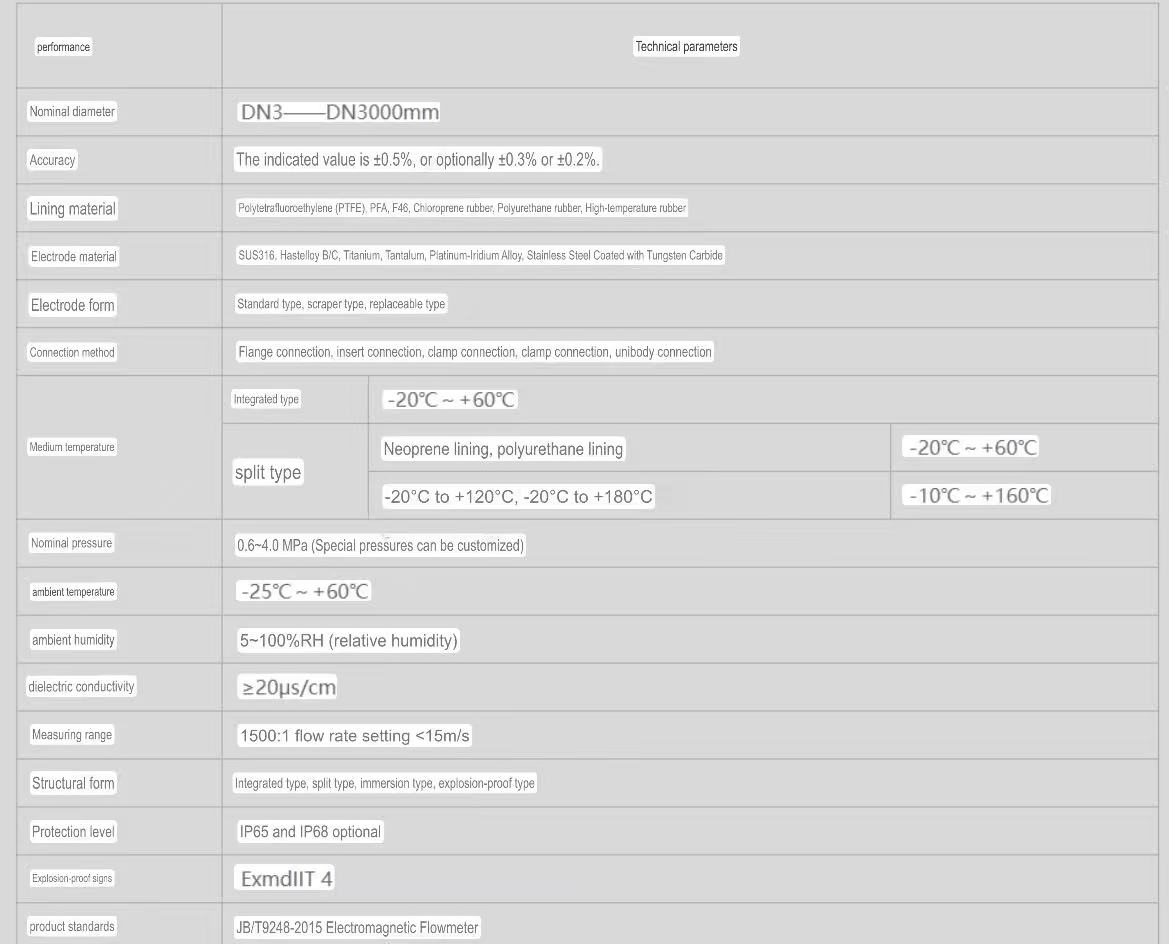

DN4-DN3000 bore flange type electromagnetic flow meter 0.5 class accuracy IP65 IP68 protection

Flange-type Electromagnetic Flow Meter ★ The measuring pipe contains no moving parts, which is for maintenance and management; there is no flow resistance component, so there is no pressure loss. ★ The measured liquid conductivity ≥ 5μs/cm, combined various lining materials, can be used to measure the flow rate of various acids, alkalis, salt solutions, and media such as mud, ore pulp, and paper pulp. ★ The measurement of flow rate is not affected by the density, viscosity, temperature, pressure, and conductivity changes of the fluid. The sensor senses the voltage signal linearly with the flow velocity, and the measurement accuracy is high. ★ Proper selection of lining and electrode materials can achieve good corrosion resistance and wear resistance. ★ Low frequency rectangular excitation, not affected by the power frequency and various stray interference on site, and operates stably and reliably. ★ Not affected by the direction of the fluid, it can measure in both forward and reverse directions. ★ Range ratio 1:120 (0.1m/s~12m/s), the full flow rate range is wide. ★ Chinese LCD backlight display, can be modified online, simple and convenient to operate. ★ It has the functions of empty pipe and alarm, and can adapt to different fluid media. ★ Power-off time record function, automatically records the time when the power of the instrument system is interrupted, and the missing flow. ★ Hour total record function, records the total flow in units of hours, suitable for time-sharing metering system. Flange-typeromagnetic Flow Plan.png Working Principle According to Faraday's electromagnetic induction principle, a pair of detection electrodes are installed on the pipe wall perpendicular to the of the measuring pipe and the magnetic line of force. When the conductive fluid moves along the axis of the measuring pipe, the conductive fluid cuts the magnetic line of force to an induced electromotive force, which is detected by the two detection electrodes. The numerical value is proportional to the flow rate, and its value is: E = KB Where: E - Induced electromotive force; K - A coefficient related to the magnetic field distribution and axial length; B - Mag induction strength; V - Average flow velocity of conductive fluid; D - Electrode spacing; (inner diameter of measuring pipe) Flange- Electromagnetic Flow Plan 1.png Product Advantages 1. The structure of the electromagnetic flow meter sensor is simple, and there are no moving parts in the pipe, and there is no throttling part that hinders the flow of the fluid; 2. It can measure the flow of dirty media, corrosive media, and solid-liquid two-phase flow; 3. During the measurement process, it is not affected by the temperature, viscosity, density, and conductivity (within a certain range of the measured medium; 4. The output of the electromagnetic flow meter is only proportional to the average flow velocity of the measured medium, and is independent of the flow statelaminar flow or turbulent flow) under symmetric distribution; 5. The electromagnetic flow meter has no mechanical inertia and is sensitive to response. It can measure instantaneous pulse flow and also measure flow in both positive and negative directions; 6. The range of selection for the caliber of the industrial electromagnetic flow meter is wide

Product selection guide

01. Measure the medium, temperature, and whether it is corrosive

2. Flow range and the inner diameter of the user's pipeline

03. Pressure class

04. Whether to display on site

05. power supply

06. Signal output, communication

07. Whether explosion-proof is required

08. Installation method

09. Accuracy class

Application field

The electromagnetic flowmeter is applied to: petroleum, chemical industry, steel, food, electric power, papermaking, metallurgy, water supply and drainage petrochemical, medical and other industries.

A device that meets the flow measurement of various industries

Installation precautions

1. Place without vibration and strong electromagnetic (such as near large motors, frequency converters);

2. Try to install vertically, and install horizontally at a low place when necessary. Do not install at the top the pipeline to ensure full pipeline and prevent bubbles;

3. Requirements for straight pipe section, it is best to ensure 10 times the front and 5 times the of the pipe diameter;

4. When installing with welding, be careful not to connect the instrument welding to prevent damage to the flowmeter;

5. The shell be grounded as much as possible, the shielding line should be grounded at one end, and the grounding point should not be shared with strong electricity;

6. If easy maintenance, the installation position needs to be selected well to meet the maintenance requirements. At the same time, a bypass pipeline can be installed, and the fluid flows through the bypass in case of fault;

7. Avoid direct sunlight and high temperature places, and do a good job of waterproofing and moisture-proof treatment;

8. Other that should be considered, the signal line should not be installed together with the strong current line.

Service we can provide, recommended selection and quotation

1. Product customization

2. 7*24 hours, national service hotline

3. On-site guidance for installation

Production process

01. Inspection incoming flange and stainless steel pipe

02. Conduit processing

(cutting, welding)

03. Inspection

04. Conit lining

05. Inspection

06. Electrode, coil processing and assembly

07. Inspection

08. Weld of shell components

09. Inspection

10. Spraying

11. Inspection

12. Transducer/ junction box assembly

13. Inspection

14. Real flow calibration

15. Inspection before shipment

16. Packaging

17. Wareousing

18. Shipping

The sensor senses the induced electromotive force E as the flow signal, transmits it to the converter, amplifies, transforms, filters it through a series of digital processing, and uses a backlit dot matrix LCD to display the instantaneous flow and cumulative flow. The converter has 4-20mA output alarm output and frequency output, and is equipped with RS-485 and other communication interfaces, and supports HART and MODBUS protocols

Product selection guide

01. Measure the medium, temperature, and whether it is corrosive

2. Flow range and the inner diameter of the user's pipeline

03. Pressure class

04. Whether to display on site

05. power supply

06. Signal output, communication

07. Whether explosion-proof is required

08. Installation method

09. Accuracy class

Application field

The electromagnetic flowmeter is applied to: petroleum, chemical industry, steel, food, electric power, papermaking, metallurgy, water supply and drainage petrochemical, medical and other industries.

A device that meets the flow measurement of various industries

Installation precautions

1. Place without vibration and strong electromagnetic (such as near large motors, frequency converters);

2. Try to install vertically, and install horizontally at a low place when necessary. Do not install at the top the pipeline to ensure full pipeline and prevent bubbles;

3. Requirements for straight pipe section, it is best to ensure 10 times the front and 5 times the of the pipe diameter;

4. When installing with welding, be careful not to connect the instrument welding to prevent damage to the flowmeter;

5. The shell be grounded as much as possible, the shielding line should be grounded at one end, and the grounding point should not be shared with strong electricity;

6. If easy maintenance, the installation position needs to be selected well to meet the maintenance requirements. At the same time, a bypass pipeline can be installed, and the fluid flows through the bypass in case of fault;

7. Avoid direct sunlight and high temperature places, and do a good job of waterproofing and moisture-proof treatment;

8. Other that should be considered, the signal line should not be installed together with the strong current line.

Service we can provide, recommended selection and quotation

1. Product customization

2. 7*24 hours, national service hotline

3. On-site guidance for installation

Production process

01. Inspection incoming flange and stainless steel pipe

02. Conduit processing

(cutting, welding)

03. Inspection

04. Conit lining

05. Inspection

06. Electrode, coil processing and assembly

07. Inspection

08. Weld of shell components

09. Inspection

10. Spraying

11. Inspection

12. Transducer/ junction box assembly

13. Inspection

14. Real flow calibration

15. Inspection before shipment

16. Packaging

17. Wareousing

18. Shipping

The sensor senses the induced electromotive force E as the flow signal, transmits it to the converter, amplifies, transforms, filters it through a series of digital processing, and uses a backlit dot matrix LCD to display the instantaneous flow and cumulative flow. The converter has 4-20mA output alarm output and frequency output, and is equipped with RS-485 and other communication interfaces, and supports HART and MODBUS protocols

Electromagnetic flow meter | Turbine flow meter | Ultrasonic flow meter | Vortex flow meter | Rotating vortex flow meter | Thermal gas flow meter | Smart water meter | Ultrasonic radar level meter | Flow meter calibration equipment | Flow meter manufacturer

For technical and business consultation, please contact Engineer Zhang

WhatsApp: 86 13430464310 Email:ingfenzhang969@gmail.com

No detailed specifications available for this product.